Ceramic Technologies is introducing the newest technology in razor blade slitting.

Our M2 Diamond coated blade will outlast any steel or ceramic coated blade on the market. We start with an extremely hard M2 tool steel blade that has a Rc55 hardness. We then Diamond coat it

to give a low coefficient of friction that will give better quality edge cuts and eliminate belled edges.

Operators can be experience the longevity of a blade that will last 16 times longer than steel blades and 2-3 X other coated blades.

Related products

-

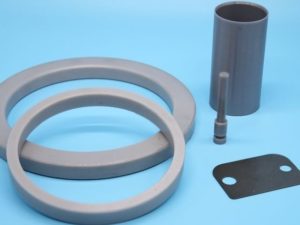

Our fine-grained sub-micron yttria stabilized zirconia is a great material for zirconia ring applications. Zirconia pad printer rings, Piston wear sleeves and zirconia bushings outperform…

-

Sintered Alpha silicon carbide is one of the hardest, most corrosion resistant ceramics commercially available. With no free silicon, this material resists even the strongest…

-

Ceramic nozzles are typically made from low cost alumina, tungsten carbide or high performance Silicon nitride. Ceramic nozzles are used in industries like the sand…