Ceramic Technologies introduces the newest improvement in Razor blade technology in 15 years. The U.S. made Tri-Coat Razor Blade is a steel blade with 3 layers of protection:

-

Base coat of Chrome reduces stress between steel and other coated layers

-

Secondary coating of ceramic significantly increases edge hardness

-

Diamond overlay reduces the coefficient of friction on the blade edge.

-

Tri-Coat blades last 12-15 times longer than steel blades along with the enhanced lubricity that improves edge cuts.

-

Cut with a sharper blade for longer periods of time.

-

Great for slitting; OPP Films (PP,OPP,BOPP), Low & High Density PE, Aluminum Foil, LLDPE, Stretch Film.

Benefits:

-

Stays Sharper Longer

-

Gives Better Edge Cuts

-

Safer: Operators do not have to change or reposition blades as much. Less exposure to injury

-

Less Downtime and maintenance

-

Increased Production

-

Less film tearing during start-up.

-

Will not break like carbide or ceramic.

-

Less chance of web breakage caused by dull blades.

-

Every saved web break= huge downtime savings!!!

-

Will outlast tool steel blades

Category: Ceramic Technologies Product Catalog

Related products

-

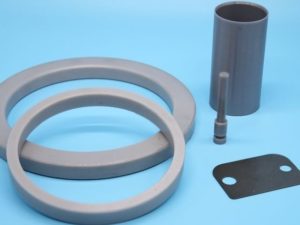

Our fine-grained sub-micron yttria stabilized zirconia is a great material for zirconia ring applications. Zirconia pad printer rings, Piston wear sleeves and zirconia bushings outperform…

-

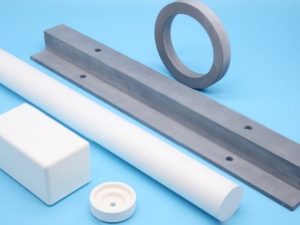

Sintered Alpha silicon carbide is one of the hardest, most corrosion resistant ceramics commercially available. With no free silicon, this material resists even the strongest…

-

Boron Nitride is a high temperature, lubricious ceramic. It offers excellent electrical resistance, chemical stability and wet ability.